At US$0.97/lb the lead price is already good, but the great news is that it is soaring. Buoyed by strong Chinese demand, the future for this dull gray metal looks bright indeed.

The most abundant lead mineral, galena (PbS) has a few favourable characteristics that endear it to the processing world. The first is it’s density which at about 7.6g/cc puts it into the heavyweight class, one of the denser sulphides out there. The second is its cubic crystalline structure which results in it breaking into very convenient little cuboids, with low surface per unit mass. These attributes render galena a prime candidate for gravity concentration, the easiest and cheapest of the processing methods. The third is that it readily responds to flotation and can be selectively collected. What doesn’t therefore collect via gravity can be scalped off in a scavenger flotation step if appropriate and necessary.

Galena responds very well to gravity as evidenced by the recovery-mass pull graph in a Knelson centrifuge test:

Interestingly, the galena responds ahead of competing minerals like chalcopyrite, pyrite and sphalerite, an important consideration when it is specifically targeted from a polymetallic host.

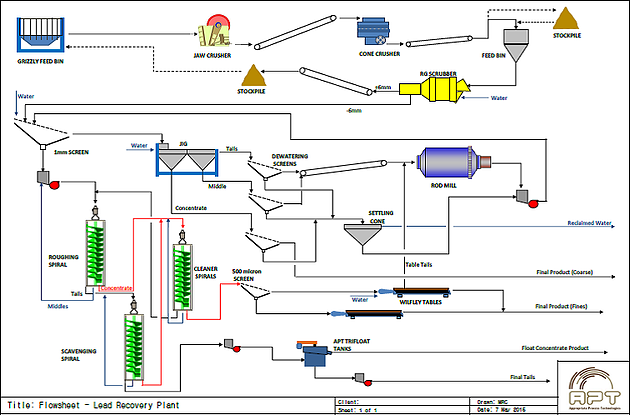

Flowsheet

The appropriate APT flowsheet is depicted below, designed for throughputs in the 20tph range although larger capacity versions incorporating FLS Knelson CVD concentrators ahead of the spirals are possible. The use of a mineral jig up front may be justified if the galena occurs in massive form and is liberated at around 6mm crush size. Likewise, a small APT TriFloat cell may be included if the galena reports sufficiently to the fines.

Plant

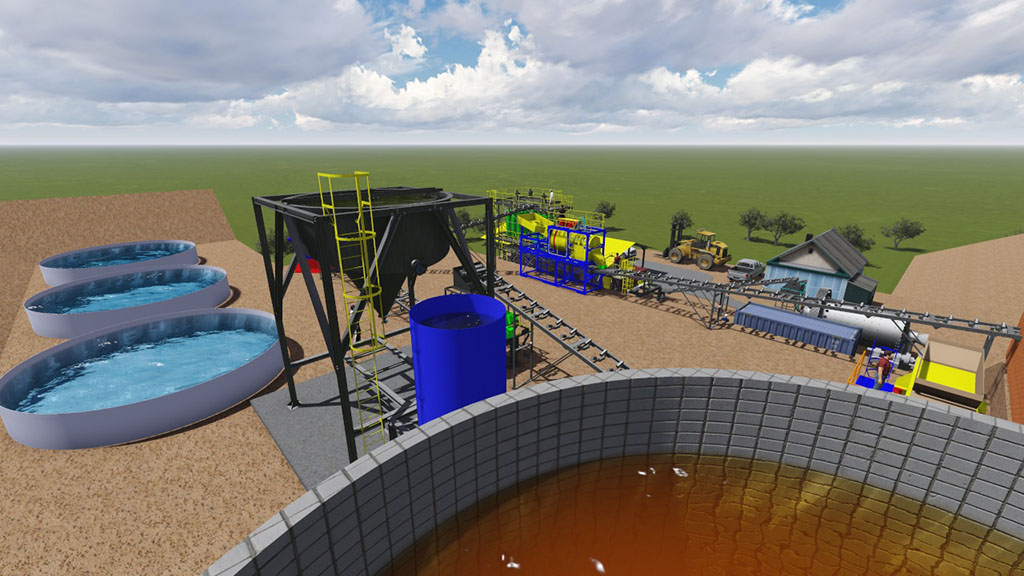

APT manufactures and supplies modular packaged process plants in a number of sizes. Apart from the advantages of a low capital outlay and short manufacturing lead time, these plants require little on-site preparation and can be installed and commissioned in a fraction of the normal time required. A schematic representation of a plant suitable for galena production is depicted below. The same operating and design principles can be applied to recover other target minerals such as wolframite, cassiterite and tantalite, amongst others.

Testing

APT offers the services of our associate laboratory Peacocke & Simpson to evaluate your ore or products. The specific advantage of utilising the P&S laboratory is their ability to perform investigative work as well as process confirmation upon a larger bulk sample. Being au fait with APT plants, testing is geared towards practicality and generates the parameters necessary to enable rapid progression to plant selection and pricing.