Starting mining can at first thought seem to be a daunting process if you are entirely new to the industry, and if you do have some experience you may have an idea of what you want but require some expertise and guidance from people who are willing to share their experience and knowledge to help you advance. Here we have developed a general guide when it comes to starting mining, specifically for the small scale entrepreneur. This article is targeted at the upper oxide near surface occurences, alluvial (surface level) or elluvial deposits that would be amenable to free dig.

NOTE! This article is not intended to be a rigorous guide to mining/processing and the opinions expressed are those of the author only. APT takes no responsibility for the outcome of your project from utilizing some or all of this information.

What to produce?

Establish what mineral or metal you want to produce, for example gold metal or chromite concentrate. You may already have this established because you know an area where it can be produced, but don’t rush in too early.

Look at the potential rewards in making your decision. Look at the price now, and the trends. For example chromite today may have only a marginal price, but on internet you can see that the price curve is going up and has been doing so steadily for some time. So if it makes sense now, it should get much better with time.

Is there an easy market for what you want to produce? How much will it cost to transport the final product to the buyer? For example a tonne of chromite concentrate will need to be bagged at the mine, trucked to a port, loaded on board, shipped to destination port and maybe even trucked to the buyer. A kilogram of gold, however, can normally be carried personally to a buying center nearby.

Is the process well known and easy, or will you have to start something completely new? The easier to do, the less risk, but if you are up to learning the ropes a lesser known product may entail less market opposition and maybe put you ahead of the pack. For example, a deposit with fine tantalite as the target is more difficult to extract than chromite, but less people can do it.

Are there any rules or laws in place that could get in the way? For example, there may be a ban on the export of chromite concentrates.

Do I have a target area?

The general proximity of most minerals is usually known, but the geology dictates that there will be zones of concentration and it is finding these that makes the difference between a good and a bad project. For example an erosional deposit that has collected into a depression will be far more productive than a thin occurrence on the back of a saddle. This is normally a job for an expert geologist and it is worth the time and money to seek their advice. We are not talking about a broad exploration programme here which is aimed at finding a large, new mineral deposit, but rather zoning in upon an area that is known to be productive from past production, or even your own prospecting.

Is there any history? Checking historical records in the local mining office will give insight to the grades they found and the production. You may also find some local knowledge from someone who once worked there. Take it all in with an open mind, you can sort out the important facts later.

Is there current production in the area? If there is, can you ascertain who is doing well and who is not? It is very easy to generate a Google Earth image of the area and you can then plot all the producers on it and then grade them by colour – red for the best going to blue for the worst, or diggings you can see have been abandoned. A line of red dots is a strong indicator of where you should be, especially if you can pick up some geological feature that corresponds to it. Look for the same feature some distance away that may have been displaced by a fault or an intrusion, and if there is no working there it becomes a strong target for you to explore.

Is this a good spot in the area?

Once you have a general area in mind, you will need to explore more closely to find the best spot. In small mining this is closing down to a few hundred square metres.

Before you can begin this process you will need to secure title to the area which can involve anything from registering claims to purchasing rights. This varies so much from country to country that it cannot be defined here, but needless to say make sure you are legal and empowered or it may all be for someone else.

Pinpoint exploration or prospecting can now begin in earnest, which as the first step usually involves panning soil samples or hand pulverized rocks on site. Only when you are sure you are zoned in is it worth submitting samples to a laboratory to quantify your findings. Submitting large numbers of blank samples is an expensive game, in terms of time as well as money. A simple field pulveriser and a set of pans should be good enough to achieve this target.

The next step is to ascertain whether you can recover the target well enough in simple processing. This usually translates into gravimetric methods to minimize environmental impact. The best way to do this is to take a few hundred kilograms of as representative a sample as possible. Include what you would actually be digging in practice, but do not include random blank gangue ‘to be conservative’. You can always bring in your factors later, but for now we need the straight facts. Give the lab clear instructions that they are to test recovery with the minimum of complexity possible. They should begin with the easy steps, like scrubbing to see what is free and liberated naturally. They can then progressively crush to see what more comes out, and finally resort to ball mill grinding to get the ultimate liberation. By plotting the recovery at each stage it is obvious where the best return comes from and that is usually in the initial scrubbing stage. APT have developed a system whereby the secondary crushing of the competent rock as well as some of the milling stage are combined in wet impacting using our own proprietary RD series impactors. One normally achieves the majority of the ultimate recovery in this simple system. The Peacocke & Simpson laboratory is equipped with all of these unit operations at bench scape to test all scenarios.

A typical test recovery result is summarized below:

Clearly in this case the majority of the recovery comes from the scrubbing (52%), but there is definitely a worthwhile target left in the competent rock, and impacting this adds a further 27% to the recovery. Ball milling the impact gravity tails to a very fine state (75 microns) only adds a further 7% recovery, so it is unlikely that that step would be warranted.

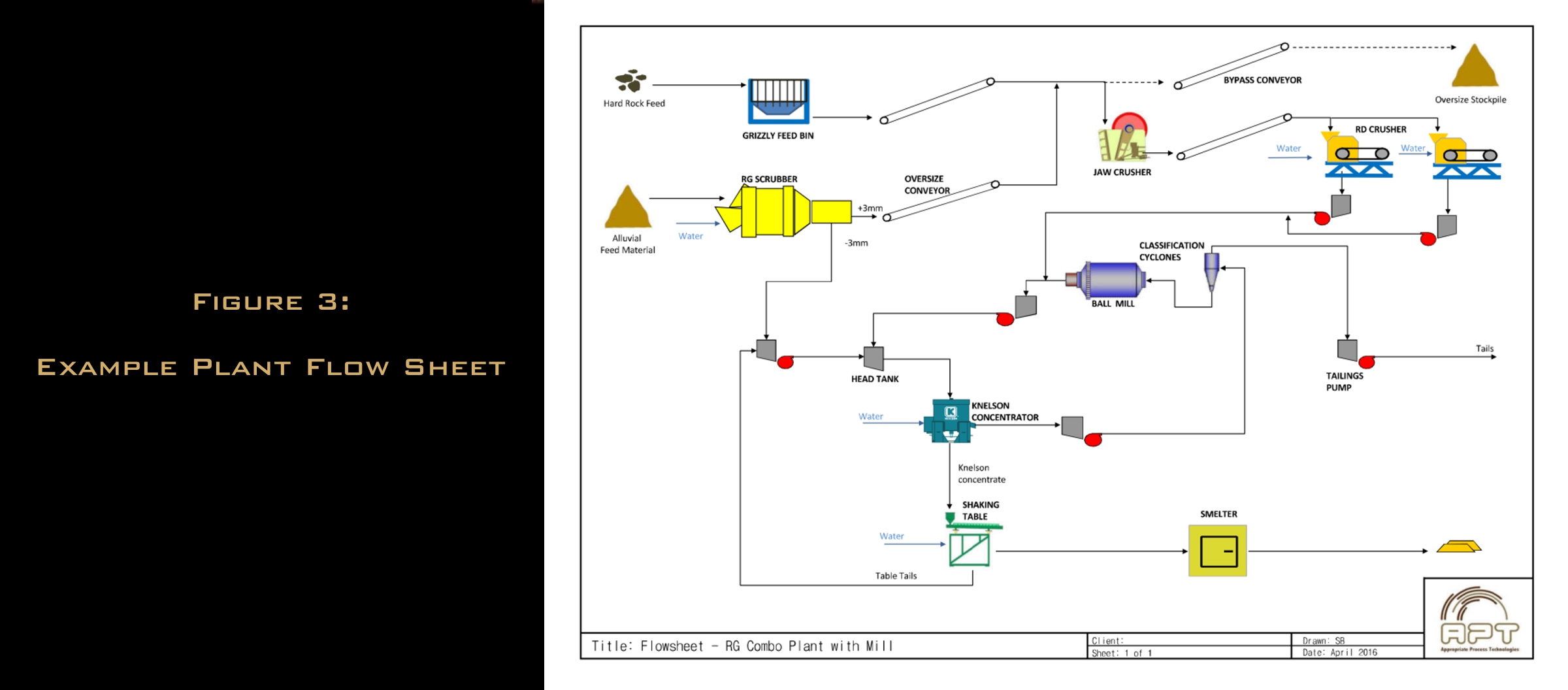

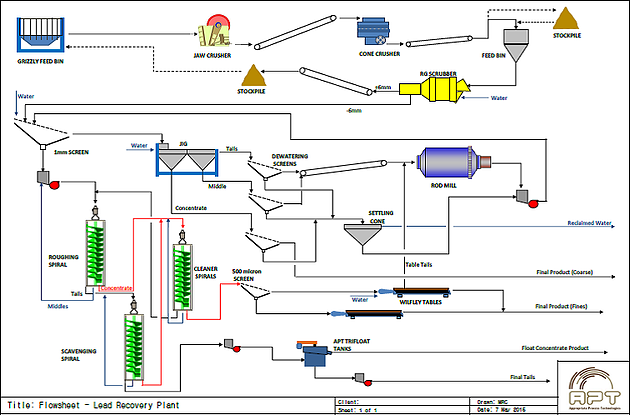

So in this hypothetical case the target flowsheet would look like this:

What sort of plant will I need when starting mining?

The flowsheet defines the optimal steps, but the next question is what scale? This is dictated by capital constraint, the rate one can dig and feed the ore, water availability and sometimes market capacity.

If it is gold you are after, the latter doesn’t arise, but just for the exercise, lets consider a tantalite case: A tantalite buyer may only want 2.5 tonnes of concentrate a month for example. So if you anticipate working 8 hrs per day, 24 days per month and the indicated recovery is 70% from an ore feed grading 0.1% Ta2O5, then the calculation looks like this: Tonnes per hour = 5tonnes/0.1%/70%/24days/8hrs = 37 tonnes per hour = 18.6 tph.

Back to gold. In this case market is infinite, and the scale is down to choices like resource size, mining capacity and capital. Keep things modest and conservative, there is absolutely no sense in going big out of the gate.

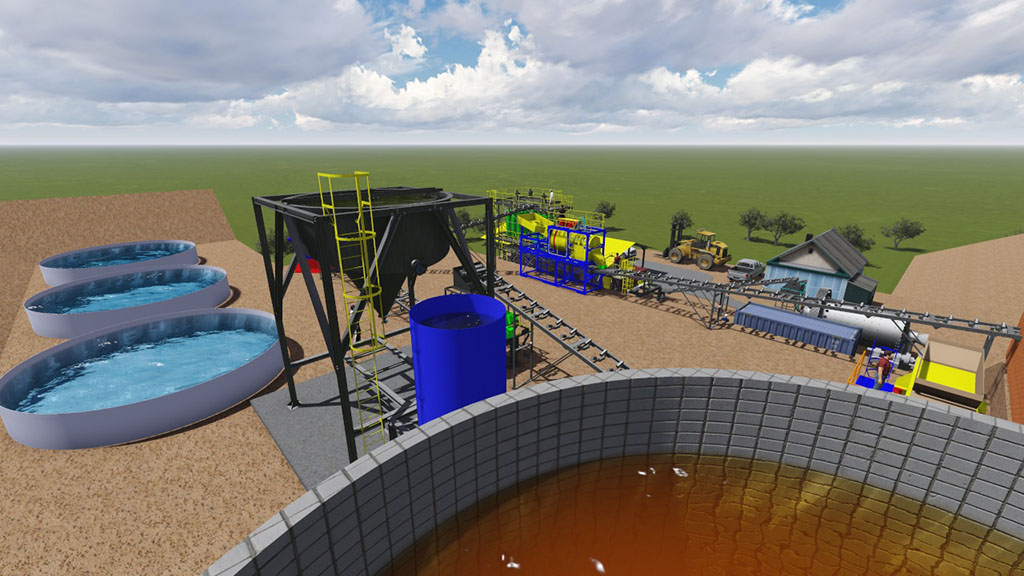

Once you have a scale in mind, contact APT for a budget price for a plant of that size to match with the flowsheet requirements. You will also receive back a very elementary 3-D schematic of what your plant would look like.

Mining equipment costs can be easily come by and APT will provide budget estimates for plants in a few size categories, all catering to those starting mining or those well-versed in the mining field. Plug these into a simple financial model, or access a simple financial model on the APT website. This will give you an idea of the viability of the project given your ore grade and expected recovery, together with input costs and of course the gold price. Go for the minimum scale that makes money, you can always grow from the returns.

Once you have narrowed down the scale you may request a formal quotation from APT.

Water

Your flowsheet and even your quotation will specify the water requirement in cubic metres of water per tonne of solid feed, usually about 2 m3 water per tonne solid.

By multiplying out the daily working hours you will know your requirement.

If you need to drill boreholes, you should get them sited, drilled and tested because if there is no water, there is no hope of mining. You may be lucky enough to have an old shaft on site to pump from, but test its replenishment.

Your water production rate from a borehole, for instance, may be less if you are processing for only 8 hours for example, but can pump for 24hrs.

If this is the case, you will need at-plant water storage. APT usually supplies one or two 70000 litre ponds. One of these can be used for recycle from the tailings pond, and one for clean water makeup from a borehole etc.

The clean water pond is then reserved for clean water users, like your Knelson concentrator if you have one, or the upgrading table.

Tailings disposal

Each country has rules governing the disposal of tailings, but it is always made easier if you are starting out with a chemistry-free gravity processing route.

Even so it is sometimes necessary to line the deposition area anyway, and in this case you need to consider a life-of-mine, calculate the tailings volume from that and hence the tailings area to be put down.

The tailings placement site should be chosen taking cognisance of the surrounding topography. The optimum situation is to choose a gentle slope with plant feed at the top, then the plant, then the tailings outwash area, then water reclamation ponds below that.

There should be three reclamation ponds; two central ones left and right with the muddy flow going into one, and then switched to the other when it is time to scoop out the accumulated mud from the first.

The far side of each of the two primary settlement ponds then overflow into the recycle water pond and the recycle pump is placed at the far side of this pond.

The recycle water should be pumped to the process water pond right at the site, as mentioned previously.

All ponds should have berms around them so that no muddy water flows in from the general surroundings when it rains.

Digging and mining equipment

Our case study is based upon surface free dig, which in the case of an elluvial deposit like chromite may involve surface scraping and loading into a tractor trailer. In this case a digger such as a backhoe may suffice. You may need two of each to make the system workable.

For an alluvial deposit, the digging may need to be more localized.

If the dig is on exposed reef along the strike then the digging may require an excavator matched to the mining rate.

In any event, APT are not mining experts and you are recommended to seek the advice of such a person or company to recommend the proper system.

Personnel

Apart from the very smallest of operations, all mining ventures require staff.

Choose people who are interested and have stamina before looking to qualifications. This is hard work with long hours and not just a job.

Make sure you get a well experienced mechanical person with some electrical knowledge to maintain and repair the equipment.

Once you have chosen your APT plant, APT can advise upon the number and grade of the necessary staff. They can also advise upon the level of expertise of the mechanical person.

Putting it all together

Now that you have defined the scale, it is time to put a plan together with a time frame and a check list of items to tick off:

Specification and selection of mining equipment

Plant siting plan. APT supplies you with a layout of the immediate plant area, so it is easy to superimpose this over your claims plan. This plan is sometimes necessary for permiting purposes.

Digging and mining equipment.

Tailings placement site.

Minimum on-site infrastructure required (an APT plant comes with an elementary workshop and one or two of the containers can be retained to turn into a site office, restroom, etc.)

Is there a road or will you need to clear one?

Operating capital to see you clear to the first product payment, or beyond.

Personnel

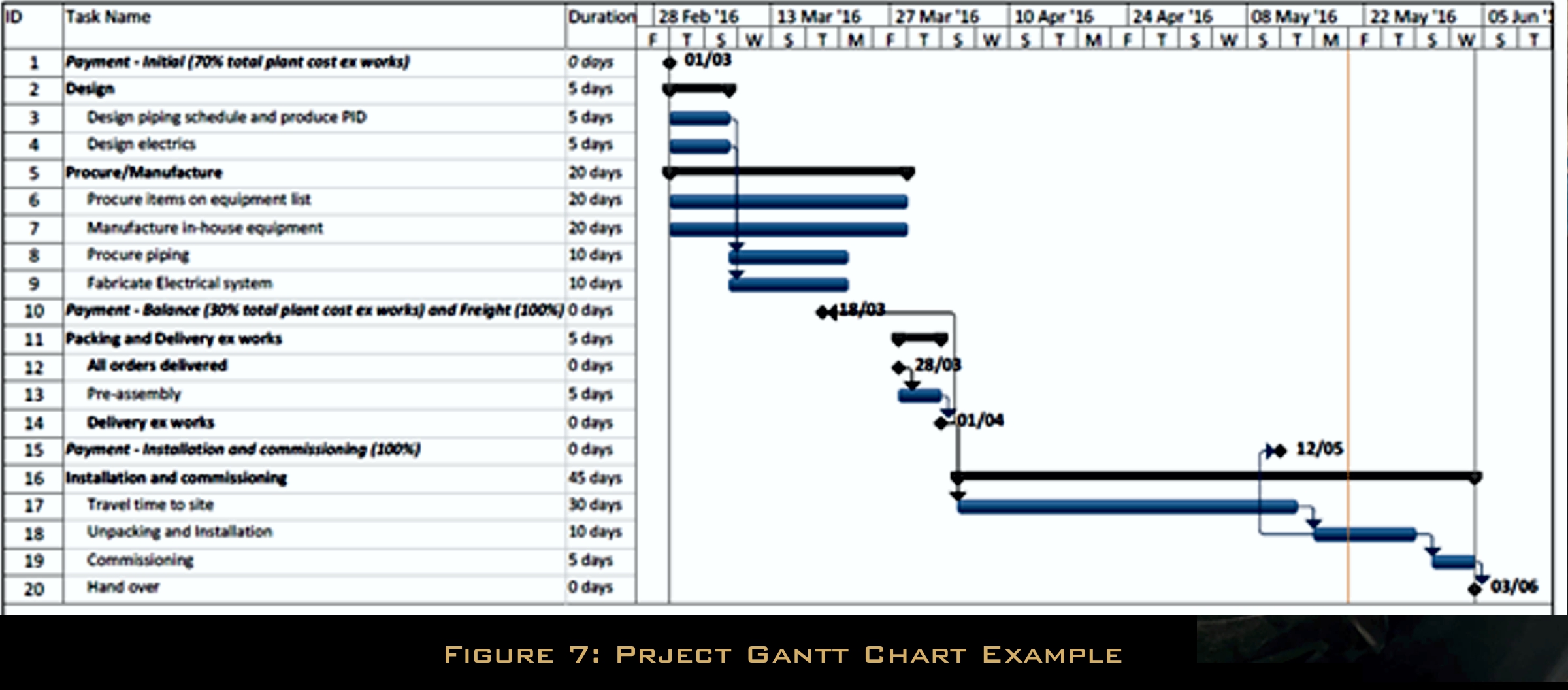

The time frame will look like a project GANTT chart, nothing more than weeks blocked out in sequence with the necessary tasks. The final task is commissioning and startup. Be reasonable with the timing and leave blocks for rest or catchup. There is nothing worse that falsely generated pressure that normally results in mistakes.

Initiation

Generally this is the fun part and where starting mining feels like a reality. Place your orders for all the requirements leaving contingency time for arrival.

Engage the contractors to prepare the site and any roads.

Get the boreholes dug and equipped if appropriate.

Engage your staff just before the plant arrives as APT will use them in the construction phase which is very good training.

Begin mining ahead of time to accumulate a stockpile.

Begin to feed your plant with the assistance and guidance of APT. This is the break-inn phase where any problems come to light and are jointly corrected with APT and your staff, again good training.

The plant will then be signed-off and you are on your way to a hopefully prosperous project future.

APT wishes you all the best starting mining from project planning to implementation – please don’t hesitate to call upon us to assist with your special project!