Seeing a plant on site brings the whole process to life for everyone involved. Here at APT we are very tight-knit with all employees playing a role in bringing our plants to life; from research and development, engineering and design, right through to manufacturing and on-site development. Not everyone gets to go to site, however, and not all of our clients know what the process is like. Here is a glimpse at one of our latest installations in East Africa, the CIL TriTank. We look forward to showing you more of our site visits in our 2 Minutes with APT series! [embed]https://www.youtube.com/watch?v=Chw_Dri8NiA[/embed]

Small Scale LITHIUM Mining Flotation Plants From APT

Lithium mining is on the rise and likely to be so indefinitely. No better time to get in, commence production and secure your market share. Things can grow, but APT’s modular start-up plants offer the perfect platform to commence the lithium mining process. Our mining equipment solutions are unique and smart. The target mineralization is typically spodumene, which floats well. APT’s TriFloat cells are particularly suited to this large mass yield float and the compact six cell design results in an easily controlled format. With the addition of a simple crusher and impactor to obtain the granular start mineral size, the plant is virtually ready to go.

Available in variants of 1.5, 5, 10 and 20tph, the APT Lithium recovery plant is highly simple, cost effective and correct for an easy startup. Through our associate laboratory Peacocke and Simpson amenability tests can be conducted at either lab (20kg sample required) or lab-pilot (60kg sample).

If you would like to begin your venture and get into profitable production as quickly as possible, then we invite you to contact us for further information or better yet, stop by our offices! It's always great to see things in person and truly get an idea of who we are.

APT – Something new, always

Coarse GRAPHITE Recovery Success In APT's TriFloat

Following our TriFloat launch, we caught up with one of our Process Engineers, Hannah Peacocke, to get an update on how the system is operating.

Laboratory results upon an African medium flake graphite ore produce a very high grade coarse graphite concentrate, demonstrating the capability of the APT TriFloat system. “Bench and pilot scale flotation produced a flotation concentrate of over 90%C upon a feed of -2mm”, said Peacocke. The concentrate was then de-gritted in a proprietary APT process, and upgraded further to 93.6%. The flake produced was far coarser than obtained in a conventional float, even upon this marginal ore, with 38% reporting to the +300 micron fraction. With a recovery of this up front coarse-scalping process of over 73%, the lab pilot test validated the efficacy of the procedure.

“The goal was to preserve as much of the coarse flake graphite as possible, and that was achieved. If necessary, further grinding and flotation upon the initial coarse tailings to increase the recovery may be carried out”, said Peacocke.

[embed]http://www.youtube.com/watch?v=54UWSql2KNI[/embed]

The entire APT TriFloat procedure can be utilized in an initial project start-up phase to commence production with the highest quality concentrate right out of the gate. Added advantages of modest capital and short lead times make the APT Graphite plant a serious contender in the current market.

Samples can be accepted for testing, please contact info@aptprocessing.com

We decided to have some fun and film a quick sample run for you! You can view it by clicking the video above!

APT - a smarter way, always

EQUIPMENT FOR START UP MINERS: What is APT's GroundBreaker Division?

Mining in the best of circumstances is challenging. You may have a mine, but how do you get the optimum value from your resource? This is where the GroundBreaker division of APT can step in to get you started. Many have become well familiarized with the APT GroundBreaker range, but for those who have just come to find us, it would be fitting to define what this range is. When speaking of the GroundBreaker division, we are referring to a range of equipment which enables anyone to start and advance in their mining development, with low start-out capital and room to grow. Firstly there are the artisanal miners who are facing various challenges and need equipment that can empower them to establish a future for themselves, then there are small scale miners looking to start on a low capital and grow through their own profit, those who are starting out in mining, those who need small scale mining equipment that is simple to use but gives efficient recovery and lastly, miners and exploration geologists who need to explore their resource. All of the above are looking for equipment that is cost effective, yet uncompromising on quality and efficiency. The GroundBreaker range has employed a minimalist design over the years with no extra complication but tough on build, this has led to this range being any small miners wish come true.

The equipment within the GroundBreaker range is available through a variety of sizes with suitable throughput capacities. The plants are robust and fully mobile, having been skid or wheel mounted for easy translocation. All of the GroundBreaker products are designed around our principle of ‘Modular Mineral Processing’, where we supply mix and match equipment to suit every situation and resource. Small scale miners, in particular have found it possible to grow their operations by starting with GroundBreaker modules and progressing through to medium and even larger scale mining equipment.

At the same time, the GroundBreaker range of equipment is in line with our started policy, entirely mercury free and environmentally caring. Good for you, good for your workers and good for the environment. The range was not designed to replace mercury, but rather to be as or more efficient and effective than the mercury alternative, thus a more attractive solution. Material can be processed efficiently, meaning higher recovery and better return. GroundBreaker equipment can be bought and set up as toll units which miners can rent for the processing of their material.

For miners starting out or serving exploration purposes, its portability is another factor. Plants are available in trailered and skid base versions, easily and swiftly disassembled, moved and reassembled. In some cases, there is no need for disassembly and re- assembly at all as everything is already set up as it should be. This range covers the entire spectrum of resources from alluvial to hard rock, and over a bouquet of minerals (some being; gold, tantalite, tine, chromite) with equipment designed to cater for the need.

Finally, you are not alone! You can access the APT technical team, who will advise you and guide you through the planning of every step from test work, financial and site planning, purchase of equipment and development of your mine. We have a dedicated GroundBreaker division who are involved in every step of the research and development, design and engineering phases. They know the equipment thoroughly, and are able to help you as required.

Contact us here with any queries, we are happy to help and look forward to hearing from you!

Recover Gold On The Move! Hard Rock Mining Equipment On A Trailer

We are proud to introduce the RDGK mining equipment trailer for hard rock gravity gold processing.

Our first ‘plant on wheels’ was the RG30-T, a trailer version of the RG30 mobile wash plant and concentrator, which was neatly and cleverly designed to allow you to simply unfold the required components and get into production quickly and efficiently. Following its success we wanted to do the same but, this time, with a hard rock plant. We are finished with the engineering, research and development and are proud to bring you the RDGK-T, a small scale hard rock plant on wheels!

Rated at approximately 1t/hr to 1.5t/hr feed in field the RD15 wet impact fines grinder is driven by a 15KW Diesel engine. Accompanied by the GoldKacha Concentrator run by a 5.5KVA Generator which can also be used to run lights and electricity if a camp is set up.

All of the above is set up on a 15inch two wheeled heavy duty fully braked trailer with spare wheel fully equipped with stabilisers and jockey wheel. There is a hand winch system to lower the GoldKacha to operating height on scissor frame.

A great mobile exploration or production plant for gold from hard rock feed of less then -30mm (feed can have up to 45 % fines inclusion) at approximately 1t/hr. (You can pre-crush feed rock with a Jaw Crusher /we have the JC25 Jaw Crusher with diesel drive on skid base available). Just hook up a 2inch petrol or diesel drive water pump to the system and you are away. (fuel consumption:- approx. 3.8lt hr diesel and 500ml petrol on genset per hour).

This mining equipment trailer hard rock plant is available in Southern Africa right now at $19950 plus VAT. Please contact us for details.

If you would like to see this plant in action before purchase, we can arrange to do a demonstration at various sites. Videos will be released online too! For the moment, please see a very basic and short video of our RDGK standalone plant video here. Please take note, this video is simply the standalone version and not the trailer version.

Please contact us for further information on any equipment. We often hold plant sales and perform demonstrations so if you would be interested in receiving this information, please email us and we will add you to our mailing list.

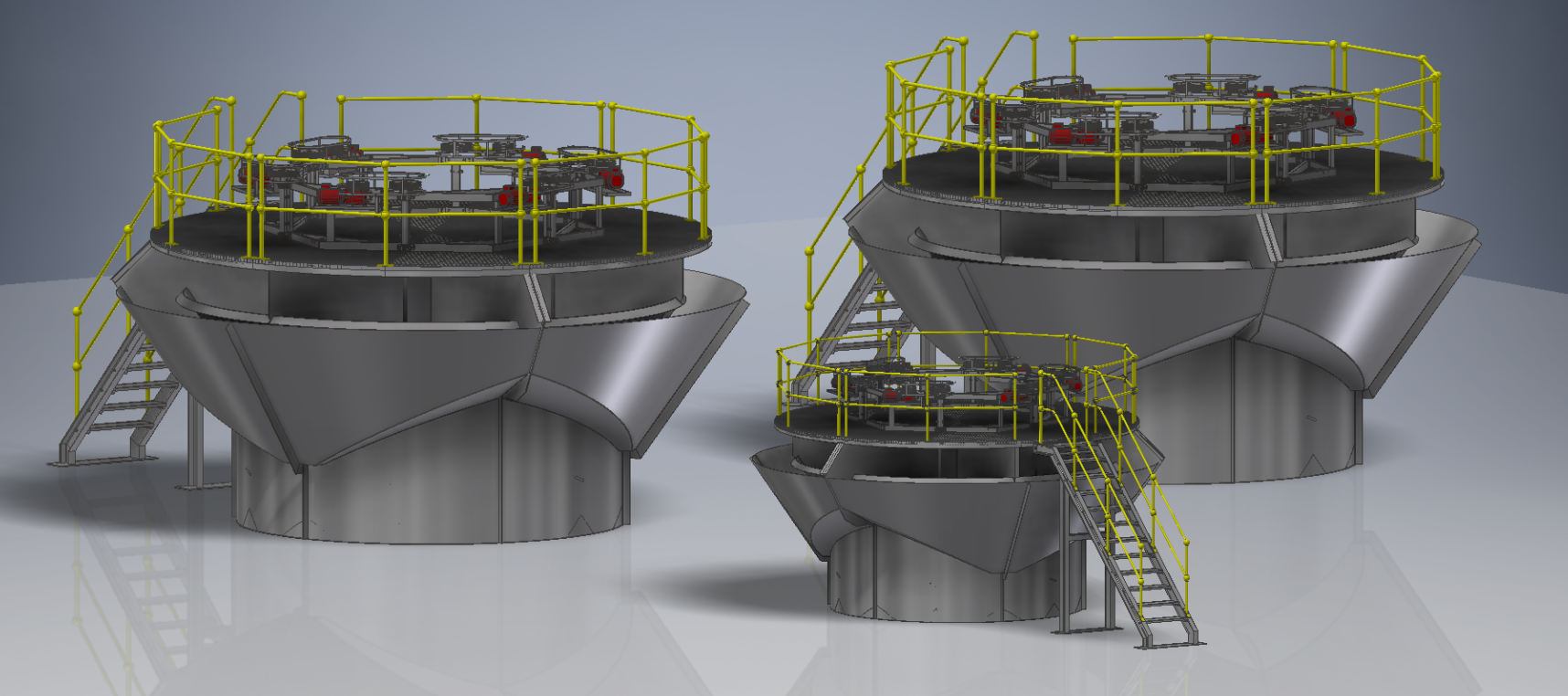

Modular Flotation System: TriFloat® is here!

Aimed specifically at the smaller to medium flotation market, APT has designed a modular flotation system that offers a number of unique advantages over conventional systems. Based upon APT's tried and tested triangular configuration mixing vessel, TriFloat® utilizes the same high efficiency mixing to enhance flotation physics and hence rate. Watch the video for the TriFloat® here! Configuration advantages

In a TriFloat® system, six flotation stages are arranged in a circle for a neat and tidy arrangement. One distinct advantage of this arrangement is that at a small scale, all six mechanisms are driven from a single central drive motor, resulting in significant space and cost savings. Another advantage is that the six sectors can be separated flow-wise and allocated to roughing, scavenging and cleaning all in one compact arrangement. APT's process engineer, Hannah Peacocke, continues "for example, the first three sectors could be roughers, the second two scavengers and the final one a cleaner. This makes the system truly modular and highly attractive to smaller operators who need flexabililty". Alternatively, a complete TriFloat® module of six sectors could be allocated to each duty as seen in the schematic below.

Schematic representation of APT TriFloat® as Rougher, Scavenger and Cleaner modules

Flow advantages

Products are easily moved around the circuit by pumps arranged radially, making for a very user friendly set up. Stage tailings simply flow through the wall to the next sector, making for a logical arrangement. With a high lip length to volume ratio, and the advantageous placement of the mixing mechanism, froth is removed easily and efficiently.

Piloting

APT has developed a bench scale system for testing as well as for making comparisons against conventional laboratory tests. A larger batch pilot unit has also been developed and tested for batch pilot testing. Initial results show APT TriFloat® to be superior to conventional square section lab flotation cells and particularly suitable for high yield materials like graphite and high sulphide materials.

Applicability testing

APT are able to test client's material through associate mineral testwork laboratory Peacocke & Simpson. Batch laboratory tests as well as locked cycle can be performed and as a subsequent phase 60kg batch pilot tests can also be conducted.

Contact us today!

Please contact us for more information on APT's modular flotation system and let us know your specific needs, as always we are happy to help and get you going on your mining journey today!

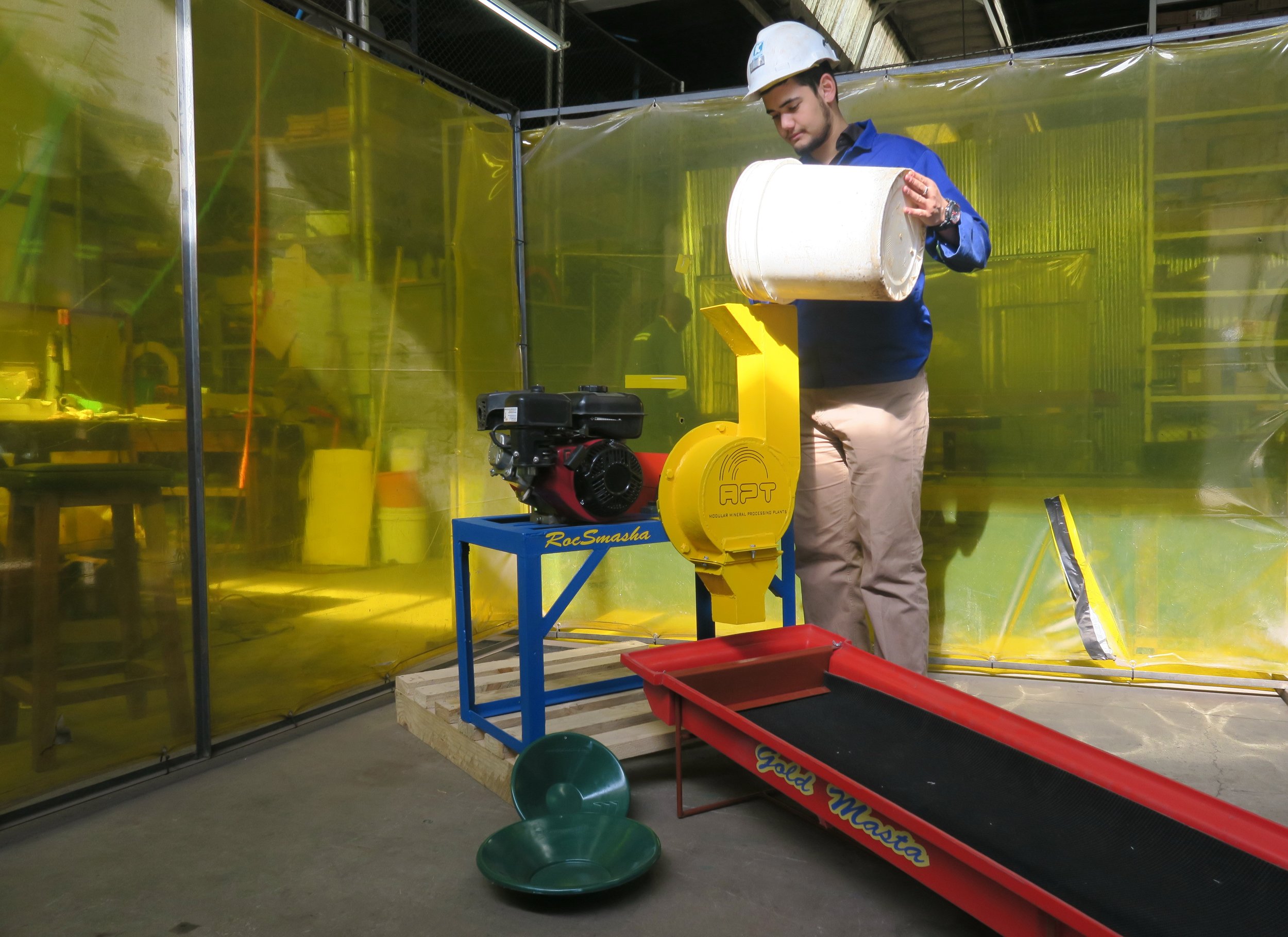

Small Scale Hard Rock Grinder and Upgrade Plant: APT RocSmasha

APT have added an innovative, cost effective new product to their Groundbreaker Range with this small scale hard rock grinder, the Roc Smasha. This small scale hard rock grinder offers a much larger range of miners the option of mechanical grinding. This means that more material can be processed increasing the probability for successful results. Its simple but functional design ensures easy use and maintenance features. The RocSmasha is portable and offers dry and wet grinding options, wet grinding ensuring no dust contamination on the environment following APT’s environmentally conscience philosophy. The RocSmasha is sold alongside the APT GoldMasta gold sluice as well as 2 panning dishes, making this a complete, affordable gold liberation kit. Interchangeable screen cartridge for ware replacement and tuning is provided. This small scale hard rock grinder plant can be purchased on APT's online store here, and more can be read about it on our website here. The RocSmasha small scale hard rock grinder has a maximum feed size of 20mm with a throughput of 50-100kg/h. Portability makes it perfect for moving from site to site either for small scale production or exploration. A 3kW Gasoline engine drive means low energy consumption. The hard rock material is fed through the feed chute using a small shovel or by hand, it is then crushed to size. The hard rock is reduced by RocSmasha’s unique offset blade hammers ensuring a high kinetic impact and “early liberation” of free gold from the inherent fracture planes, further reduction grind is imparted through the grinding path within the easy change screen plate cassette.

The wet slurry discharge is fed onto a GoldMasta Sluice over the unique APT GoldMatt ensuring very efficient recovery of free gold, (the APT GoldMatt being washed out at intervals for free gold collection). This small scale hard rock grinder plant is the perfect affordable mining solution.

For minerals such as tantalite, tin, tungsten etc. the screen plate cassette aperture can be changed easily to suit mineral type and a special type of vortex matting is placed in the sluice tray for best recovery of these minerals.

Entry level mining’s new dynamics: An artisanal approach

Mining across the globe has for very many years been stuck in a time warp at entry level. Most entry level artisanal miners are still relying on archaic methods of processing despite major technological advancement in this field. This is due to many factors. These artisanals have little spare means and in many cases may rely on milling centres that may employ low recovery up front methods. Of course there are other parameters that dictate mineral processing at this level. Such as seasonal mining, to suit climatic and agricultural needs. Often we see that artisanal miners drop mining for agriculture or vice versa, as and when the season suits. If they do it is usually because they may not have time to undertake both. With this in mind, APT have developed a range of entry level mineral processing systems that can save the artisanal miner much time and thus ensure that both mining and agricultural practice can be employed concurrently. Not only is this vital aspect is addressed, but also the mineral processing will be cleaner and more efficient. Sure there is the cost factor up front for such new processing that could balk artisanal miners. They do quickly grasp the benefits in recovery and time, and with correct guidance are able to embrace the new methods.

There are a number of ways where the APT Groundbreaker technology can be incorporated into Artisanal Mining operations, which will benefit communities and the environment as a whole. Let’s go over these briefly; enter the junior mining companies that require good corporate social responsibility programmes. And, the entrepreneur who has access to means, who may well be in a position to assist and offer a synergistic arrangement that benefits both the entrepreneur and the artisanal miners. Or, environmental and aid organisations, that are looking at best practices in the field. Equally, the artisanal miners can, themselves, consider forming cooperatives to offer best practice processing centres on a combined level.

APT are always available to discuss the benefits of their product range, which can be configured to each miners particular needs. This includes gravity gold and silver processing, on surface oxides (mercury free), or coltan in surface resource, tin, chromite and gemstones. We want interact with the miners for the benefit of mining communities as a whole. We assure you of our whole hearted effort to ensure correct and optimum processes are delivered.

Obviously all the aspects mentioned above require commitment in the form of financial input and in, field participation and work. APT are open to discussing your needs. Foremost is the fact that the entry level miner usually exists on both agricultural and mining for a living, moving between one or the other as the weather dictates.

Over the past few years, APT has been steadily proving up and entering into the market a range of innovative minerals processing equipment, specifically aimed at artisanal miners which will improve the efficiency, profitability and environments efficacy of their operations. Having identified the need for this technology, APT have done numerous field and laboratory trials ensuring optimum environmental and recovery methods.

CATA Mine Tanzania Pours First Gold

CATA Mine in Tanzania, has produced their first gold pour and we at APT send them a hearty congratulations! The CATA gravity and cyanidation plant was supplied and installed by APT in response to the mine’s request to have the best technology available. APT responded with the supply of a gravity tower including the renowned Knelson concentrator coupled with a top of the range Consep Acacia reactor to treat gravity the Knelson gravity concentrates. The gravity tailings are then treated in two of APT’s state of the art TriTank reactors in CIL mode. Reagent dosing, elution and smelting completes the package. At a startup capacity of 40tph and further modules can be added to double that throughput.

“We believe this is the most advanced gravity/cyanidation package operating in Tanzania”, said business development officer Gary McFarlane. “It is a flagship APT installation that both we and the client can be justifiably proud of”, he said. The plant was also supplied with one of APT’s Field Laboratories with facilities to monitor plant performance as well as undertake analysis of exploration samples.

“We are currently in the process of supplying the much smaller APT TriTank20, especially designed to offer the same advanced technology to small scale operators. This not only demonstrates our commitment to the smaller players, but also offers a means for larger mining houses to pilot this advanced system”, said McFarlane.

We wish CATA every success in their future operations, it is a pleasure to have been of service to this forward thinking mining company.

Fig 1 CATA tower and tanks under construction in record time

Figure 2 The completed installation – neat, tidy, functional and efficient

Should you wish to know anything more about APT's gravity/cyanidation plants, please give us a phone call on (0027) 11 704 6678 or email us on info@aptprocessing.com. We look forward to hearing from you!

Mining Equipment That Is Simple, Clean and Efficient: the signature of tomorrow’s plants

Mine Equipment That Is Simple, Clean and Efficient – the signature of tomorrow’s modular mineral processing plants

Have you ever walked through the set-up of a large minerals processing plant and seen obvious flaws like mis-routed piping, stairways climbing over and around obstacles, etc? Chances are that it was also a mess with slurry all over the place and puddles here and there.

Apart from the difficulty of working with and in such an environment, you can bet your bottom dollar that there is a real cost to be paid for this, because inefficient engineering means inefficient operation.

Nothing is perfect, but we at APT are constantly striving to get closer and closer to it. APT’s plants incorporate surge capacity at critical points and planning for overflows, should they happen. Logical flow is as important as flow logic, carefully planning routings from the 2-D flowsheet to the 3-D installation.

Ergonomics, ease of maintenance and, and yes, a good looking plant are all objectives of the process. If it looks good it is invariably pleasant to work in and believe it or not, studies have shown that a pleasant environment results in higher productivity from the workers. Clean, neat and tidy unit operations are also much easier to automate, should that be required at build or in a subsequent phase. APT’s designers pay particular attention to spacial arrangement and pleasing aspect. Our plants are colourful, good looking and inviting to operate in. All plants should be functional, but APT is looking to go well beyond that to another level of operability.

Fig 1 Alluvial + Hard Rock Mine Equipment; an APT RD50 Combo plant. A clean and tidy arrangement.

Fig 2 APT complete (12 sector) CIL TriTank plant, extremely neat and tidy and the benefits of this design go well beyond aesthetics

Fig 3 The mine equipment shown here is the same plant as the above, here you can see an adjacent gravity tower with intensive cyanidation module in the base.