We are proud to introduce the RDGK mining equipment trailer for hard rock gravity gold processing.

Our first ‘plant on wheels’ was the RG30-T, a trailer version of the RG30 mobile wash plant and concentrator, which was neatly and cleverly designed to allow you to simply unfold the required components and get into production quickly and efficiently. Following its success we wanted to do the same but, this time, with a hard rock plant. We are finished with the engineering, research and development and are proud to bring you the RDGK-T, a small scale hard rock plant on wheels!

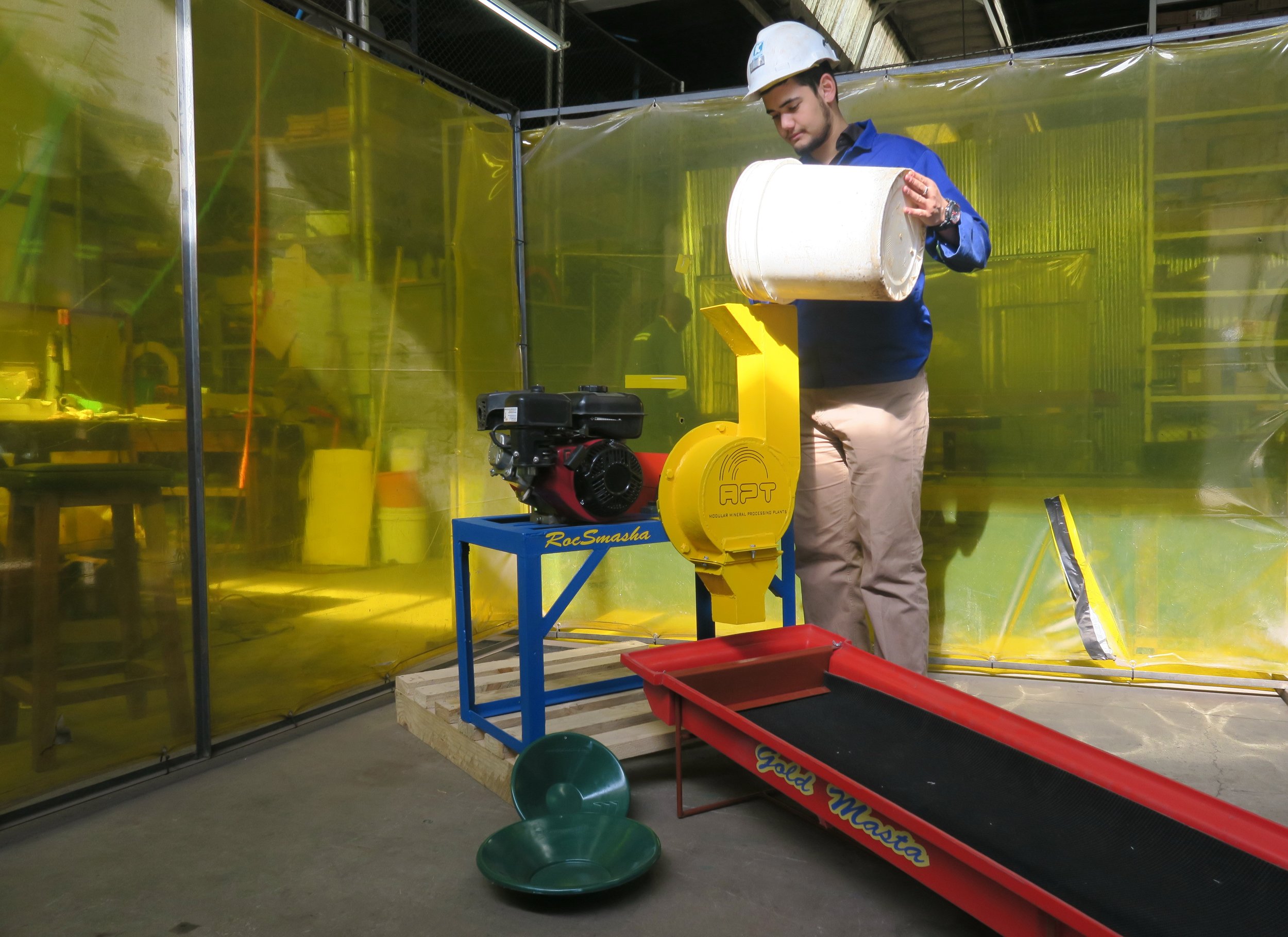

Rated at approximately 1t/hr to 1.5t/hr feed in field the RD15 wet impact fines grinder is driven by a 15KW Diesel engine. Accompanied by the GoldKacha Concentrator run by a 5.5KVA Generator which can also be used to run lights and electricity if a camp is set up.

All of the above is set up on a 15inch two wheeled heavy duty fully braked trailer with spare wheel fully equipped with stabilisers and jockey wheel. There is a hand winch system to lower the GoldKacha to operating height on scissor frame.

A great mobile exploration or production plant for gold from hard rock feed of less then -30mm (feed can have up to 45 % fines inclusion) at approximately 1t/hr. (You can pre-crush feed rock with a Jaw Crusher /we have the JC25 Jaw Crusher with diesel drive on skid base available). Just hook up a 2inch petrol or diesel drive water pump to the system and you are away. (fuel consumption:- approx. 3.8lt hr diesel and 500ml petrol on genset per hour).

This mining equipment trailer hard rock plant is available in Southern Africa right now at $19950 plus VAT. Please contact us for details.

If you would like to see this plant in action before purchase, we can arrange to do a demonstration at various sites. Videos will be released online too! For the moment, please see a very basic and short video of our RDGK standalone plant video here. Please take note, this video is simply the standalone version and not the trailer version.

Please contact us for further information on any equipment. We often hold plant sales and perform demonstrations so if you would be interested in receiving this information, please email us and we will add you to our mailing list.