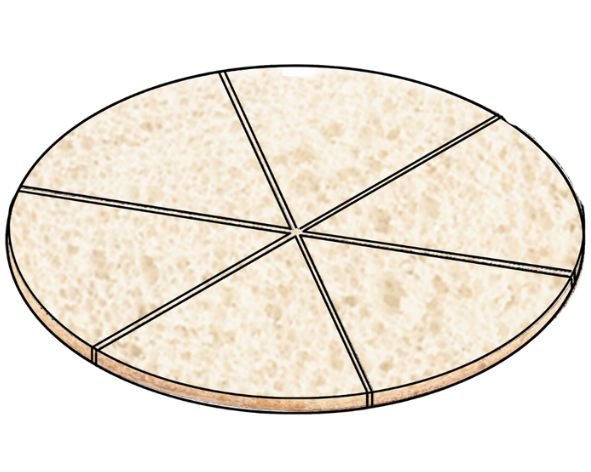

The Best Shaped Reactor

The triangular shape of each sector, together with some special base additions, results in very high mixing rates far better than cylindrical tanks.

Compact Shape and Small Footprint

There is no CIL system more compact than the APT TriTank. Apart from using less ground area, the unit is far easier to surround with a protective berm as required by law in many countries.

Immense Strength

The APT TriTank structure is effectively cross braced sixfold! There has never been a collapsed TriTank and there never will be.

Top to Bottom Mixing

The slurry in an APT TriTank is mixed vertically from top to bottom, not horizontally around. This results in excellent mixing for dissolution, and also eliminates segregation of carbon from top to bottom.

High Efficiency Interstage Screening

As the TriTank sectors are adjoining, the radial walls can be used for interstage screening. APT uses wedgewire screen panels at the top of each wall as the perfect solution to interstage carbon screening. The top to bottom motion of the slurry continually sweeps the screens clean, resulting in faultless operation. When it comes to maintenance, the screen panel housing design incorporates a parallel groove which allows for the fitment of a secondary panel, which can be put in place whilst the primary panel is removed for cleaning and maintenance. This means there is no interruption to operation.

Increased Dissolved Oxygen Levels

Due to the top to bottom mixing, the slurry is continually being exposed to air at the surface of the tank resulting in an increase of dissolved oxygen levels of up to 30%!

Faster Dissolution Rates

The excellent mixing coupled with the elevated dissolved oxygen levels results in faster dissolution rates and higher overall recovery. This also leads to the possibility of a smaller CIL plant installation.

APT Manufactures and Installs

The APT TriTank manufacture has evolved to the point where the precision made components are shipped to site in containerised cassettes. The APT team then rapidly assemble the tank on your site free of hassles. There is no faster installation available!

Available in Stainless Steel

Speak to our engineers about specialised applications - the APT TriTank is an ideal reactor for most chemical reactions.